WHAT IS REMANUFACTURING?

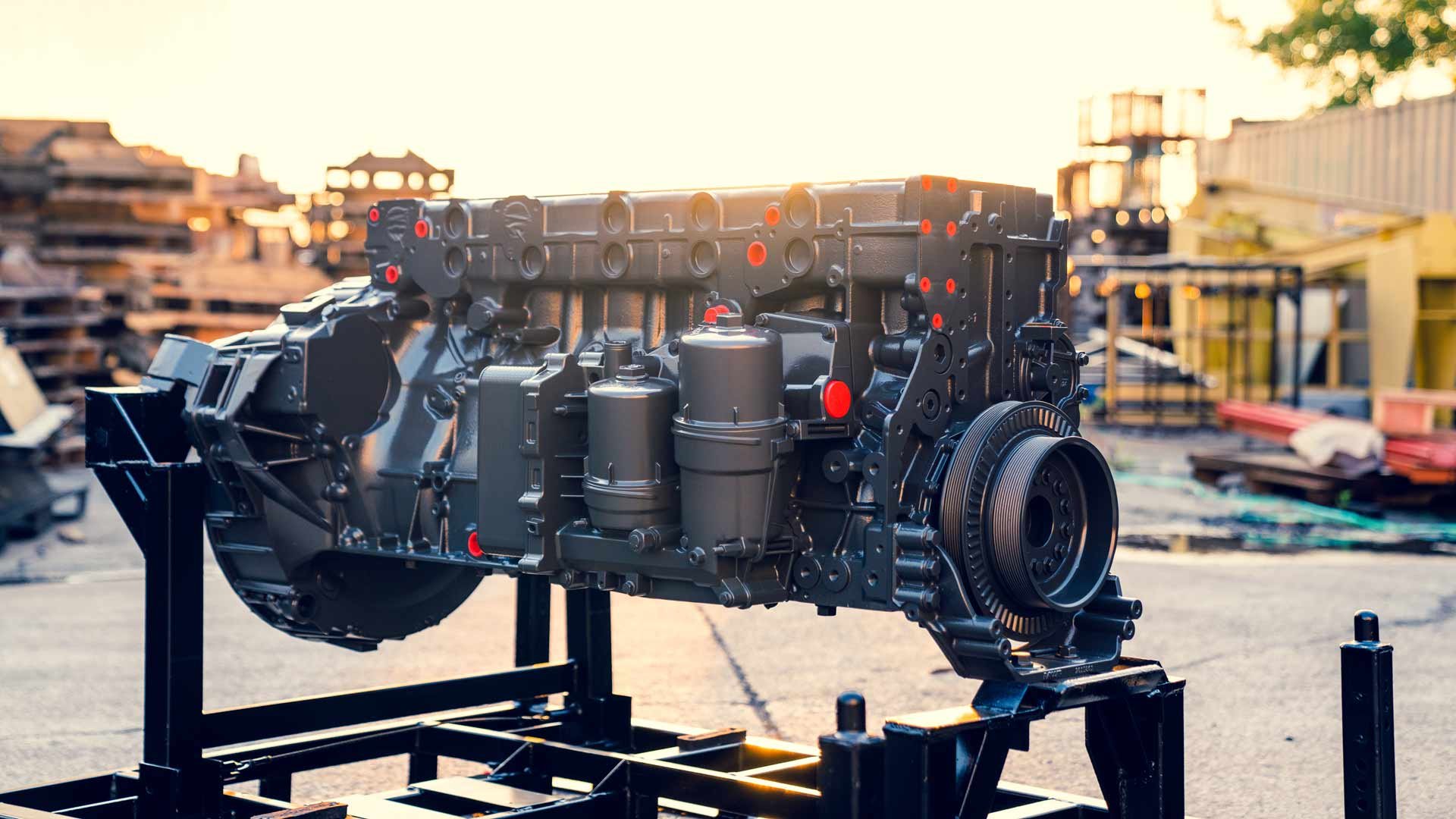

Remanufacturing, or reman, is the comprehensive industrial process by which a previously used, worn, or non-functional product or part is returned to a like-new or better-than-new condition, from both a quality and performance perspective. Reman gives products a new life cycle and keeps material out of landfills.

SRC was founded in 1983 as a remanufacturer. We have expanded our expertise over the years, but remanufacturing remains our core business. Reman offers high quality products while supporting environmental sustainability and affordability.

Quality

Properly remanned products are stripped down to their basic components and taken through a full, high-standard manufacturing process and quality testing, making them as good as when they were new, or even better. They meet the same specifications, come with full warranties, and look identical to new products. The remanufacturer is also able to eliminate known weaknesses of the original product, giving way to better-than-new quality.

Affordability

Remanufactured products are significantly less expensive than new products, offering 30% to 60% cost savings for consumers.

convenience

Reman shortens supply chains and supports local jobs, meaning customers maintain equipment uptime.

Sustainability

Reman keeps old parts and materials out of landfills and requires significantly less resources. On average, remanufactured goods save 85% of energy, water and material use compared to new goods.

The Reman Process

Our highly skilled technicians disassemble every engine down to individual components and perform a comprehensive parts cleaning and inspection before initiating the rigorous reclamation process. Precise machining brings valuable parts back to life while our manufacturing system ensures the highest level of production and quality control. These components are then assembled into a complete remanufactured product, which is thoroughly inspected to ensure it meets our high quality standards as well as OE Specifications.

The Reman Industry

Remanufacturing has been around for more than 80 years and played a role in the U.S. mobilization and victory in World War II. Since then, it has grown to a $160 billion per year industry worldwide. The current main reman industry sectors include:

Automotive

Aerospace

Machinery

Medical Equipment

Heavy Duty Equipment

Office Furniture

Consumer Products

Information Technology

Electronics

Locomotive Systems

Restaurant Equipment

Tires

Interested in remanufactured goods?

Want to know more about what we do? Click here for additional information about remanufacturing and our many other services.