Sustainability

Sustainability is the core of the remanufacturing process. Remanufacturing keeps material out of landfills, requires fewer natural resources and creates less air pollution compared to manufacturing new goods. Further, SRC Companies recover scrap material and recycle unusable materials to protect the environment.

Of energy, water, and materials saved compared to new goods.

85% //

Pounds of material saved from landfills annually by SRC Companies

286 million //

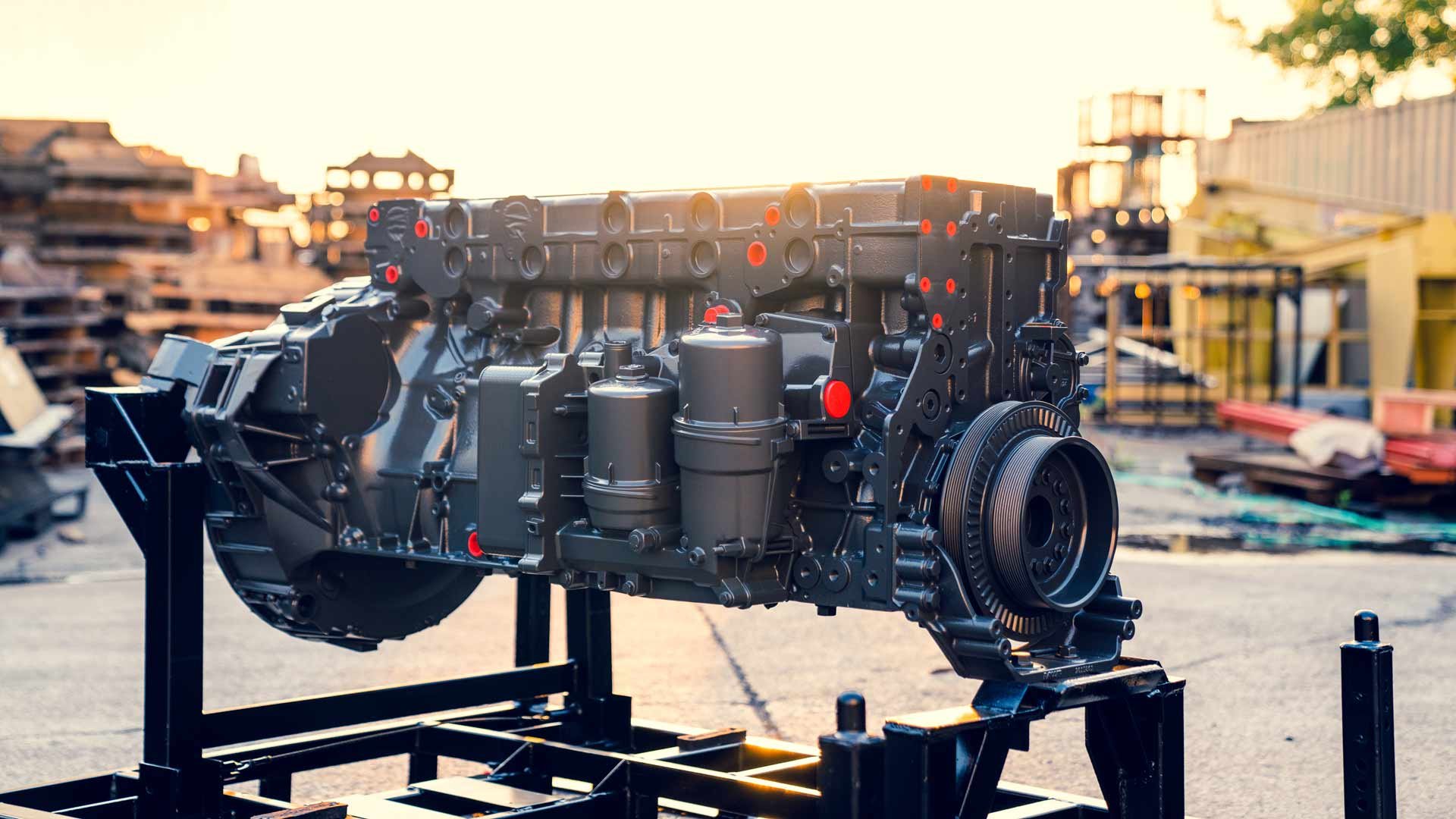

New vs. Reman

When a new product is made from scratch, it involves hundreds of steps leading up to the actual manufacturing process. The demand for raw materials, energy and other resources when manufacturing new products is continually increasing.

The remanufacturing process returns a used, non-functional product to like-new or better-than-new condition. Reman gives old products a new life cycle, keeps waste out of landfills and saves valuable resources while eliminating pollution required for manufacturing new products. Remanufacturing helps consumers maintain a lower cost of ownership, shortens supply chains and protects our planet.

Open-Book Management & Sustainability

SRC’s unique approach to sustainability is driven by our open-book management philosophy. When associates are transformed into thinking like innovative business partners, their capacity to drive green initiatives within our organization broadens drastically.